D 0.5 Particle Size

Simulation results of separation performance Ep a and D 50 b as a function of distribution parameter σ j for different median particle size d 05 when the MC ratio is 56. Accelerate the design of fit-for-purpose particles obtain new experimental insights.

Table 2 Cumulative particle size distribution at 10 50 and 90 of the given powder samples.

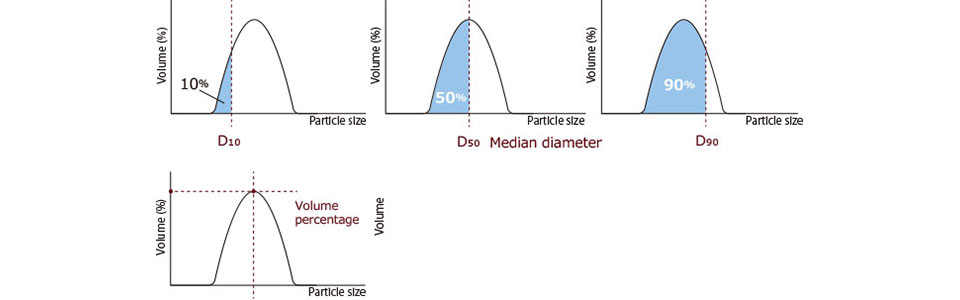

. If we take the maximum length of the particle and use this as our size then we are really saying that our particle is a sphere of this maximum dimension. D50 2540 µm. Sensitive to small particles 10 of the particles lie below this diameter 90 of the particles lie below this diameter half are smaller than this diameter half are larger than this diameter Most Common Statistics.

The distribution of talc particles is displayed in volume as well as number of particles. Dv01 Dv09 Size µm D43 sensitive to large particles D32 Dv05 median Dv10 Never use the D100. Ad Real-time particle size shape analysis for laboratory and process environments.

The relative standard deviation RSD is usually used to characterize the size distribution range of the standard particle. Clearly if we look at our particle under the microscope we are looking at some 2-D projection of it and there are a number of diameters that we can measure to characterise our particle. Q_n d int_0d q_n d Qnd 0d qnd Parameters.

Simulated partition curve in the DMC at different values of the distribution parameter σ j when particle median size d 0. When RSD is smaller than 50 the ratio of maximum particle size. The more acceptable particle size range is 4823 μm 32.

The shorthand is usually written as d or x with a. X parameter usually D for diameter a distribution weighting eg. Particle size for a given percentage volume of the sample.

50 sometimes written as a. A simple example is shown below. For this distribution the following results were calculated.

There is some change in the particle size distribution with varying disperser pressure. The variability in each set of measurements is a result of the variability within the sample itself. Measure Rheology Particle Size Particle Shape Particle Concentration and More.

Computes the cumulative distribution density function of a continuous particle size distribution at a specified particle diameter an optionally in a specified basis. Look at the particle size in a microscope and choose a lens capable of measuring the largest particles see Remarks 71. Percentiles are of utmost importance.

Particle size reports use notation specific to the field that may not be intuitive. These intervals are also called size classes or fractions. ZFor spheres of a single diameter d the only factor affecting the packing is the finite size of the container D zThe packing fraction was measured as a function of dD for containers with cylindrical symmetry.

5 mm 10 mm 15 mm and 40 mm. N for number v for volume i for intensity B percentage of sample below this particle size eg. Figure 6-2 shows a particle size distribution.

Nevertheless a wide range of particle size distribution is possible for nasal delivery of pharmaceuticals documented in contemporary literature ranging from nano-size 33 to 45 μm 34 or even up to 125 μm 35. Here a mixture of grinding balls has been separated by size. D 32 2280 µm.

Given the broad range of particle sizes in this samples some variation such as that shown above is expected. D 10 1460 µm. Particle size distribution of STP and SIA by DLS are represented in Figure 2.

Examination of STP distribution by volume demonstrated the following distribution of d 01505 μm d 052657 μm d 095512 μm and a range of 0399 μm. A particle size distribution indicates the percentage of particles of a certain size or in a certain size interval. D43 the mean diameter over volume also called the de Brouckere mean The example results shown in ASTM E 799 are based on a distribution of liquid droplets particles ranging from 240 - 6532 µm.

The d05 or 50 value was used as the average powder particle size for this study. Prepare the instrument for measuring in wet mode using IPA as the liquid as described in the user manual. Measure the background for IPA.

The powder size distribution of the samples analysed using the Malvern Matersizer Microplus laser diffractometer technique. Adopt characteristic value of particle size distributiond01d05d09known standard particlesto evaluate the instrument. Ad Malvern Panalytical is a Leading Provider of Scientific Instrumentation.

The evaluation function varies with the distribution chosen. Percentiles are defined as XaB where. The following are common terminologies associated with particle size data presentation.

The stirrer regulator should be set at 2000 rpm on the Malvern unit. D d η06050004 045007 Extrapolated to infinite container size D this represents 06050741 82 of.

Particle Size Distribution An Overview Sciencedirect Topics

Method Of Particle Size Evaluation Of Ground Material The Global Standard For Mixing Defoaming Dispersing And Pulverizing Thinky Corporation

No comments for "D 0.5 Particle Size"

Post a Comment